(Solution) CIPS Strategic Supply Chain Management APSS

- The supply chain mapping for an organisation spend category is influenced by several elements, among them environmental scanning to identify the micro and macro factors.

- Other aspects considered in the mapping are the facilities, location, and time.

- In the implementation process, it involves making suitable changes and adding value to the process.

- Drawing from the STEEPLE, Porter’s five forces, SWOT analysis, and Kraljic matrix, some of the key elements are the relationship with the vendors, consideration of various competitors, and ensuring customised category of spend.

- Quality and timely delivery of the spend category is also an important consideration area.

New User Gifts

First Order Deal get Ksh 200 Off.

£ 30.00 Original price was: £ 30.00.£ 10.00Current price is: £ 10.00.

Payment Methods:

Description

Question

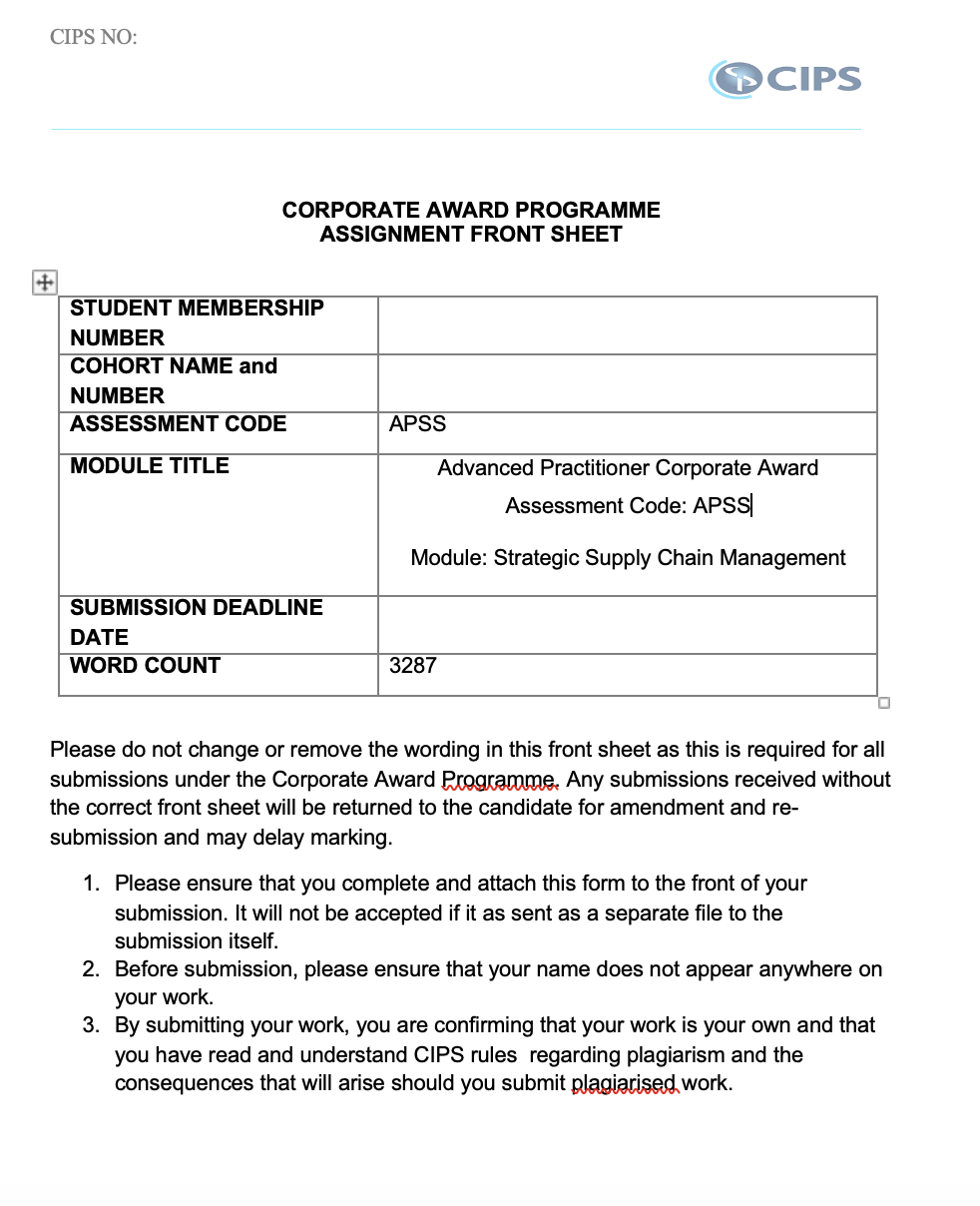

Advanced Practitioner Corporate Award

Assessment Code: APSS

This assessment tests the learning outcomes and module content of:

Module: Strategic Supply Chain Management

Task

Produce a supply chain map for a category of spend of your choice from your organisation.

Using this map analyse and contrast the strengths and weakness of the supply chain(s) and discuss the impact

of these on your business unit and wider organisation.

Note

The focus for this (and all of these) assessments is to assess the Knowledge and Capability of candidates,

effectively: “Does the candidate know?”; and “Can the candidate do?”.

This question gives you an opportunity to choose which supply chain or supply chains you want to address,

even if you don’t actually work with a supply chain yourself.

Solution

Executive Summary

This report entails the supply chain mapping of laptops for BP, an oil and gas company in Oman. The analysis draws from various models and frameworks across different dimensions, such as environmental scanning, competitiveness, and value chain. The supply chain map considers a wide range of issues and aspects, including the source of the raw materials, assembly point, warehouses, and the return of products that do not meet the expected quality. From the analysis, there are several elements that influence the supply chain mapping, including effective relationships with the stakeholders, environmental scanning, and informed decision making process. Time is also crucial in the mapping process to ensure that the laptops are delivered in time and according to BP’s preferences.

An evaluation of BP’s supply chain management and mapping process reveal that the company has put into consideration several aspects to enhance its procurement process, including technology and risk management. Throughout the tiers, BP increases visibility and relationship with the suppliers and other stakeholders. However, there is need to develop its resilience to shocks, such as COVID-19. The short and long-term recommendations to enhance the supply chain mapping include data management for improving the relationship with stakeholders, environmental scanning to aid in the decision-making process, building resilience for unprecedented issues, and learning and development of the employees to enhance their skills and competencies.

Table of Contents

1.2 Company Procurement Department 4

2.0 Supply Chain Map and Analysis 6

2.1 Supply Chain Mapping of the Laptops 6

2.2 Driving Value of Procurement 8

2.3 Supply Chain Analysis and Contrast 11

2.4 Strengths and Weaknesses of Laptop Supply Chain of the Company. 11

2.4.3 Porter’s Five Forces. 14

2.5 Impact of Laptop Supply Chain. 16

1.0 Introduction

The unprecedented occurrences at the workplace, competition, changing consumer preferences, and risks imply the need for developing effective supply chain processes to ensure that the raw materials, products, and services are available in as required. This introduces the importance of profound supply chain mapping. According to Mubarik et al. (2021), the supply chain mapping concept involves the documentation of information across the stakeholders, including individuals, suppliers, and the involved companies in the supply chain process. The supply chain mapping is a crucial element in the supply chain management. According to the Chartered Institute of Purchasing and Supply (CIPS), an effective supply chain management process entails how the flow of goods and services is handled (CIPS, 2021). This implies that various stages are factored in, from the manufacturing of the raw materials to the production and consumption by the customer. An important aspect about the supply chain process and mapping is that it requires a profound networking of the suppliers, who serve as the links to the chain and product movement through the different stages. This is essential in identifying opportunities and averting potential risks.

1.1 About the Company

The supply chain mapping is centred on the British Petroleum (BP) in Oman, which is committed to fostering the country’s sustainable development. This is achieved through supporting the local firms, developing capabilities, and corporate social responsibility. The country, Oman, continues to strategically ensure that economic diversification is achieved. According to Kirichenko et al. (2020), the diversification ensures empowerment of the local talent. BP has a history of exploring and producing oil and gas in the Middle East. BP is characterised by a high production volume of 1.5 billion cubic feet of gas and 65,000 barrels daily. The high production is crucial in sufficing the global demand of oil and gas.

1.2 Company Procurement Department

BP works with more than 40,000 diverse and global suppliers in more than 70 states. This implies that the company has to develop a robust supply chain management process, defined by strong relationships with the suppliers and contractors. As noted by Taherdoost and Brard (2019), the relationships are crucial in delivering the company’s aims and a net-zero ambitions. BP’s procurement and supply chain is guided by the sustainability objective. Every supplier is expected to share the company’s values and strive for excellence and innovation in delivering their products and services. The effectiveness of the procurement and supply chain process at BP is based on several aspects, including the application of technology and risk management. According to Handfield et al. (2019), the role of technology is to enhance tracking of the procurement process, while the risk management strategies are aimed at mitigating potential drawbacks in the supply chain process. The application of technology is reflected in the dedicated supplier portal. Some of the merits associated with the portal include access to real-time information, such as the invoice, consolidated and global view of the activities, ability to change the information, access to support and help, and tracking the progress of the responses and queries.

BP’s procurement department comprises of three tiers. At the apex of the hierarchical structure demonstrated in figure 1 below is the procurement and supply chain manager. The second and third levels are provided in the figure below.

Figure 1: Procurement Department at BP (Source: Author).

The procurement department is divided into three sections, headed by various directors. These include account management, strategic sourcing, and ICT and training. Each section has unique roles and responsibilities, which are headed by different managers and supervisors. The divisions are essential in creating flawless procurement and supply chain process (Bienhaus and Haddud, 2018). This is aligned with several aims and objectives, including the ‘Aim 20’ which ensures a sustainable supply chain process and activities.

2.0 Supply Chain Map and Analysis

The CIPS outlines some of the consideration factors in mapping the supply chain. These include recognising the risks, creating visibility, and building an effective map (CIPS, 2013). Working out the risks in the supply chain process commences by understanding the suppliers at different tiers. This ensures a sustainable brand name and value. Creating visibility involves having adequate information about the suppliers and categorising them based on how accessible they are. The pre-requisite is to develop a co-ordinated supplier database and detailing each supplier at various levels. Building the map is approached from a standardised approach to managing the required supplier information.

2.1 Supply Chain Mapping of the Laptops

The category of spend is the laptops. Presently, the company uses the HP laptops. Key elements guiding the supply chain process include the number of employees, which stand at 5000, creating a collaborative framework with various stakeholders, the integration of technology, and competition among the suppliers. The estimated period for the supply chain process, inclusive of the upstream and downstream is 6 months. As evidenced in the supply chain map in figure 2, there are two months spent between the sourcing of the raw materials to the assembly point or country, which is China. The next two months are spent between the production and the delivery to the warehouses. 30 days are spent between the warehouses to the various selling approaches, including direct sales and online process. BP has an opportunity to select the type of purchase strategy to apply, although it can order for the laptops, which can be delivered to the company directly. An important player in the supply chain mapping is the software organisation.

Figure 2: Supply Chain Mapping for Laptops (Source: Author).

Implementing the supply chain map for BP’s laptops further focuses on identifying important areas that add value and making the required changes. Among the core elements in the supply chain mapping is saving on the costs. Porter’s five generic forces can be applied in this regard, specifically the cost leadership dimension. According to Islami et al. (2020), cost leadership is aimed at reducing the delivery costs of the services and products to the customer, which ensures that the firm is profitable. Key aspects that BP questions its supply chain map is how the costs can be reduced, reinvestment of additional profits, and how the saved costs are passed to the firm’s strategic planning and competitive advantage. The cost differentiation is centred on the activities at the different tiers (Wang-Mlynek and Foerstl, 2020). In the first tier, it comprises the production partners, the second tier of suppliers comprises of the source of suppliers for the first tier, and the third tier involves the companies working in the raw materials. A critical issue across all the is the availability of the semi-conductors, which may significantly affect the supply chain process, in terms of the costs and timely delivery of the assembled units.

Applying the cost differentiation from Porter’s five forces, BP selects the most suitable company to supply its laptops. The cost aspect is centred on company that offers the highest value. Saving the costs from the laptops supply is transferred to the production process and the value to the customers. In the differentiation aspect of the Porter’s generic forces, BP engages with the company based on the innovativeness. In BP’s procurement process, it shares its specifications to the various suppliers, which informs the research and innovation process. A crucial aspect is to also develop laptops and associated products, including the software according to the company’s preferences. In the supply chain mapping, a crucial element is time (Bianchini et al., 2019). The effectiveness of the portal is to track the supply chain process to ensure that the products are supplied within the expected time.

2.2 Driving Value of Procurement

An effective procurement process is structured, visible, and cost saving. According to Tukuta and Saruchera (2015),…………………………….

Please click the icon to access this assessment in full

Related Papers

(Solution) CIPD Summarise the main points of discrimination legislation. (AC3.3)

(Solution) New CIPD 5C003- Professional Behaviours and Valuing People

(Solution) Market Research and Analytics ABS BBA in Marketing

(Solution) CIPS Module 3 Sourcing Essentials (PSE)

- Streamline the PQQ process to reduce onboarding time and ensure suppliers meet compliance and quality standards more efficiently.

- Cultivate long-term relationships with key suppliers for critical infrastructure projects to ensure timely and high-quality delivery.

- Use data analytics to enhance supplier evaluation, improving decision-making accuracy and reducing supply chain risks.

- Increase the use of eSourcing tools to boost competition among suppliers, potentially reducing procurement costs.

- Regularly run mini-competitions to ensure competitive pricing and maintain high service quality.

(Solution) CIPD Level 7 7HR02 Question 2 (AC 2.4) how the organisation can improve the effectiveness of its employee induction programme

(Solution) CIPS New Global Strategic Supply Chain Project

- The purpose of this project is to evaluate supply chain automation by leveraging Industry 4.0 technologies. The identified technologies include Artificial Intelligence (AI) and Machine Learning (ML) noted as critical for streamlining operations and obtaining value-for-money outcomes. This has been pursued by focusing on Wood Plc.

- To conclude, the generated findings of this report evidence WPC is today adopting the application of iSourcing in their procurement and supply management (PS&M).

- In the current project, through an evaluation of options for automation of the organization PS&M, the findings evidence the existence of different limitations hindering the success of their system. The issues of cost overruns, lack of collaboration, and inefficient supply chain as the organization is expanding its current operations have been noted to include limitations of their current sourcing.

- Success in the automation of their supply chain has been identified to lead to the following outcomes;

- Organisation achievement owing to automation of their supply chain, increased confidence and capability, talent management, and employee competency

- Improved stakeholders relations (a later section of stakeholders analysis) easing the change process. Through the iSourcing improvement, WPC would be in a position of harnessing technical and commercial evaluation processes.

- Increased and robust systems and policies which mitigate overall gaps in sourcing system transformation

- Today, only lower than 10% of the entire WPC resources are used to prioritize automation and IT integration successfully. Automation would improve the use of resources in their operations

- Involve their IT and finance departments to ensure within a period of 6 months they

- WPC needs to consider embracing sustainable practices as part of investing in their Industry 4.0 technologies

- Through the adoption of automation, better communication systems backed by AI and ML would be introduced to achieve 70% increased communication effectiveness.

- It is important to increase this through increasing collaboration and alignment of all their interests holistically

- Partnering with institutions for the provision of capacity development opportunities for the PS&M teams and other organizations for the success of the automation process

- Expanding their sourcing of Industry 4.0 technologies. This is to involve highly reputable global companies hence efficient operations and integration of AI

- Source of support from the government to ensure that they are facilitated in terms of policies and appropriate regulations to guide the automation process.