-63%

Description

Related Papers

(Solution) CIPS Module 3 Concept of the “Battle of the Forms”

(Solution) Sourcing essentials (PSE) Facilities management category

This report evaluates and compares four key sourcing approaches: sole, single, dual, and multiple sourcing, within ROSHN, focusing on facilities management as the primary category of spend.

Facilities management is chosen due to its critical role in maintaining ROSHN’s large-scale residential projects and ensuring operational efficiency.

Each sourcing approach is analysed for its advantages and disadvantages, and its applicability to specific procurement needs is explored using strategic tools like the Kraljic matrix and supplier preferencing models.

For instance, sole sourcing is applied to specialised maintenance services, while single sourcing is used for cleaning services due to quality control needs.

Dual sourcing is chosen for security services to mitigate risks, and multiple sourcing is recommended for office supplies within facilities management to foster competition and innovation.

A detailed supplier appraisal checklist for the facilities management category is developed using Carter’s 10 C’s model to ensure a thorough evaluation of supplier capabilities. This checklist ensures that ROSHN selects suppliers who meet stringent quality, reliability, and cost-effectiveness criteria.

The findings highlight the importance of strategic sourcing in maintaining ROSHN’s competitive advantage in the Saudi Arabian real estate market.

The following recommendations aim to optimise ROSHN’s procurement processes, ensuring efficiency, cost-effectiveness, and resilience in its supply chain:

- Conduct thorough market research using tools like Porter’s Five Forces and PESTLE analysis to understand the supplier landscape and market dynamics better.

- Integrate advanced eSourcing tools, including ERP systems and eAuctions, to streamline procurement processes and increase efficiency.

- Adopt dual and multiple sourcing strategies to mitigate risks, enhance competition, and ensure supply continuity for critical categories.

- Develop and maintain strong supplier relationships through continuous performance evaluations, clear communication, and strategic partnerships.

- Provide training and development opportunities focused on strategic sourcing, negotiation skills, and advanced procurement technologies.

(Solution) CIPS Advanced Practitioner Corporate Award Global Strategic Supply Chain

- In this assessment, the focus has been on evaluating global strategic approach for WoodPlc supply chain identified.

- The relevance of this is informed by assumption that supply chain is anchored on the need to influence changes in market in supply chain practices. This is while sustainable global sourcing strategies being used.

- The findings evidence strategic logistical impact of an organisation and supply chain management process has an impact on corporate performance. The different tools and techniques which have been applied inform on the best practice of the organisation operations.

- For WoodPlc organisation working in oil and gas contracting sector in UAE, reviewing of their supply chain is used by use of best practice in their practice.

- Also, an identification of entire risks, issues incurred and opportunities evident.

(Solution) CIPD Level 7 7HR02 Question 1 (AC 1.1) Analyse one external and one internal factor that is shaping the organisation’s resourcing and talent strategy

(Solution) CIPD Question 2: Evaluation of Individual and Team/Company-wide Contingency Pay Scheme

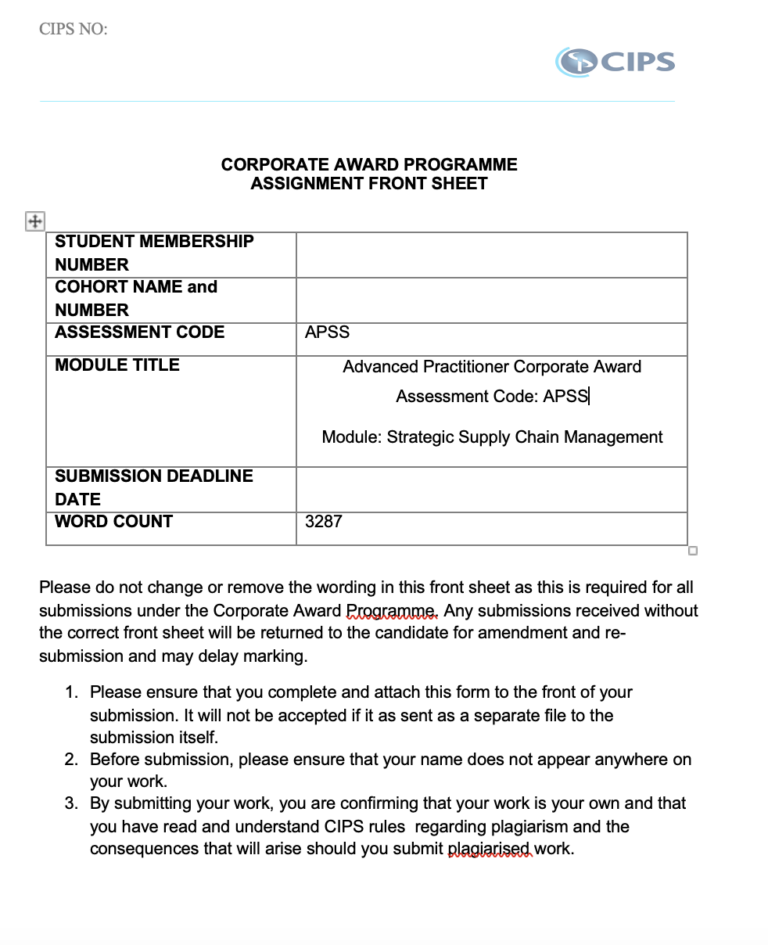

(Solution) CIPS Strategic Supply Chain Management APSS

- The supply chain mapping for an organisation spend category is influenced by several elements, among them environmental scanning to identify the micro and macro factors.

- Other aspects considered in the mapping are the facilities, location, and time.

- In the implementation process, it involves making suitable changes and adding value to the process.

- Drawing from the STEEPLE, Porter’s five forces, SWOT analysis, and Kraljic matrix, some of the key elements are the relationship with the vendors, consideration of various competitors, and ensuring customised category of spend.

- Quality and timely delivery of the spend category is also an important consideration area.